|

Flash Chrome Flash Chrome

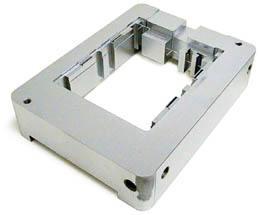

Our primary service of chrome plating is

directed at the tool & die and mold making industry. We specialize in the flash chrome

plating of core pins, cavity blocks, inserts, and laminates requiring specific deposits to

maintain close tolerance stack-up dimensions. Ideal for wear surfaces such as interlocks,

mold chases, moveable cores, and slides.

Properties: Properties:

Lubricity. Enhances mold release.

Uniform deposit thickness. Where necessary,

conforming anodes are used to insure uniform deposit thickness. This can be achieved to a

tolerance of two tenths (.0002) of an inch.

Hardness. 68-72 Rc. Ensures longer tool

life.

Protects

repairs. When repairs are made with a softer material, such as weld or nickel, chrome

offers protection against galling and premature wear. Protects

repairs. When repairs are made with a softer material, such as weld or nickel, chrome

offers protection against galling and premature wear.

Hydrogen Embrittlement Relief

Hydrogen embrittlement relief of heat

treated tool steels is done as requested or when necessary. Baking of parts will remove

the hydrogen before it has a chance to become ingrained and be susceptible to fracture by

embrittlement. |